rockness hardness test|fingernail mohs hardness : importing The differential depth hardness measurement was conceived in 1908 by Viennese professor Paul Ludwik in his book Die Kegelprobe (crudely, "the cone test"). The differential-depth method . See more Resultado da Conjunto de shorts Tiedie. A Ghetti Store sempre foi um sonho que começou a se tornar realidade neste ano de 2022 de forma online. Aqui .

{plog:ftitle_list}

Resultado da We would like to show you a description here but the site won’t allow us.

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). There are different scales, denoted by a single letter, that use . See moreThe differential depth hardness measurement was conceived in 1908 by Viennese professor Paul Ludwik in his book Die Kegelprobe (crudely, "the cone test"). The differential-depth method . See moreThe Rockwell hardness test can be conducted on several various hardness testers. All testers, however, fall under one of three categories. Bench model hardness testers can be found . See moreThere are several alternative scales, the most commonly used being the "B" and "C" scales. Both express hardness as an arbitrary See more

• International (ISO)• US standard (ASTM International) See more• Brinell hardness test• Hardness comparison• Holger F. Struer• Knoop hardness test See more• Video on the Rockwell hardness test• Hardness Conversion Chart• Rockwell to brinell conversion chart• Hardness Conversion Table See more The Rockwell Hardness Test uses a depth-differential method to test for hardness. A predetermined minor load is applied to the test sample, and the depth .

Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined .

rock hardness test kit

Learn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from Struers, the . Definition of a Rockwell Hardness Test. The Rockwell test measuring the depth of penetration of an indenter under a large load compared to the penetration made by a preload. Hardness is defined as a .Rockwell hardness test sesuai ISO 6508 / ASTM E18. . Dengan bantuan kedalaman lekukan permanen h, Rockwell hardness (HR) kemudian dapat dihitung menurut rumus yang ditentukan dalam standar ISO 6508 dengan .See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .

Brinell and Rockwell Hardness Conversion Chart - These Conversion Tables presents data in the Rockwell A, B, C, D, E and F hardness range on the relationship among .The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject. First, an indenter is forced into the test subject under an initial load of 10kg-f, and the depth is recorded.

The Rockwell hardness test and the Rockwell superficial hardness test. The significant difference between the two test classifications is in the test forces that are used. For the Rockwell hardness test, the preliminary test force is 10 kgf (98 N) and the total test forces are 60 kgf (589 N), 100 kgf (981 N), and 150 kgf (1471 N).Scope: Rockness hardness ASTM D785 test method includes two different procedures for testing the indentation hardness of plastics and plastic-related electrical insulating materials using the Rockwell hardness tester. The Rockwell Hardness Test is a hardness calculation that is dependent on the net increase in depth of impact when a load is applied. Hardness numbers . The concept of the Rockwell Hardness test is essentially similar to its counterparts. A sample material is fed on to either a digital or manual Rockwell hardness tester which would then drop a set load ending with an indenter on the surface. Then, the strength of the material will be determined by the nature of the indentation left on the sample.

Steel Hardness Conversion Table. This table shows approximate hardness of steel using Brinell, Rockwell B and C and Vickers scales. These conversion charts are provided for guidance only as each scales uses different methods of measuring hardness. The right hand column show an approximate equivalent tensile strength. In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm serves as the indenter. The indentation depth can be read directly from a dial gauge via the traverse path of the testing machine.Guides to Hardness Testing. Hardness Conversion for Rockwell C Scale or High Hardness Range . In this test method, the minor (preload) is always 10 kgf. The major load may be any of the following loads: 60 kgf, 100 kgf, or 150 kgf. Superficial Rockwell Testing.

Standard Rockwell Hardness Test Blocks - ASTM E-18 and ISO 6508; Superficial Rockwell Hardness Test Blocks - ASTM E-18 and ISO 6508; Brinell Hardness Test Blocks — ASTM E-10 and ISO 6506; Vickers and Knoop Hardness Test Blocks - ASTM E-384 and ISO 6507; If you have any other questions or would like to obtain a personal quote, please click here. C. Dampak Hardness Test pada Analisis Kegagalan Material. Dalam analisis kegagalan material, hardness test memiliki peran penting dalam mengidentifikasi penyebab kegagalan dan memahami karakteristik deformasi atau retak yang terjadi pada material. Beberapa dampak pentingnya antara lain :

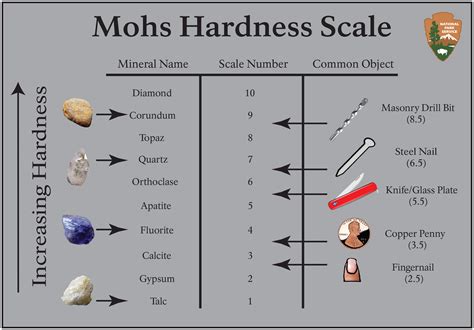

mohs' scale of hardness

Brinell hardness test is an indentation hardness test. It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the material for a set amount of time (between 10 – 30 seconds, known as the dwell time).

Basic principle and practical procedure of the Rockwell hardness test - Testing machine, test piece, conical diamond indenter - Basic principle, hardness d.

Rockwell Hardness Test is one method of testing the hardness of a material and uses the Rockwell scale based on indentation hardness of a material. History of the Rockwell Hardness Tester Hugh M. Rockwell .ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview . The second approach is by correcting the hardness test values using the indenter's area function determined by a highly accurate stylus profilometer. In the stylus profilometer developed in this .The Rockwell method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6508, ASTM E18). The process is used to test hardness in the macro range (test force >= 49.03 N), more precisely with a test force of 29.42 to 1471 N. It is a differential-depth method.

A hardness test’s immediate result is that you will eventually get to the material’s breaking point. Even tests when the specimen breaks shouldn’t be written off as a waste of time. In the event that a material does fracture under the load, a Rockwell Failure Analysis must be performed right away. This procedure is intended to make it .

The Brinell hardness test. The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically.The Ball Indentation Hardness test (ISO 2039-1; DIN 53456) is used in Europe much more often than in North America. The Barcol hardness test is sometimes chosen for thermoset polymers. The figure below, from Mitsubishi Chemical Advanced Materials, shows the .The Rockwell hardness test method, as properly defined in ASTM E-18 standards, is the most commonly used hardness test method among all the other methods. + 86 755 61301520 [email protected]

While the Rockwell hardness testing scale is prevalent, it is best to consider the material thickness and softness to select the most suitable scale between Rockwell B (HRB) and Rockwell C (HRC). This article compares two types of Rockwell hardness to help you find the most ideal of the two for your hardness testing and conversion needs.3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

The choice is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1/16, 1/8, 1/4 and 1/2 in. diameter steel ball indenters. Often an engineering specification is established at the material design phase and the operator can rely on . The Rockwell hardness test, developed by Stanley P. Rockwell, is another widely used method for measuring hardness. It involves applying a minor initial load, followed by a major load, and then measuring the depth of penetration. The hardness value is determined based on the difference in penetration depth under the two loads.Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

mohs scale test pic

mohs hardness scale scratch test

Resultado da 4 de dez. de 2023 · Reprodução. O “Jogo do Tigrinho”, cassino on-line do tipo caça-níquel, é investigado pela polícia. Nas redes sociais, .

rockness hardness test|fingernail mohs hardness